Product Description:

As a leading manufacturer specializing in rotational moulding production, we offer an extensive range of high-quality rotational moulding products designed to meet diverse industrial needs. Our expertise in the rotational molding process enables us to produce parts ranging from small to very large sizes, with dimensions extending up to several meters. This capability allows us to serve a wide array of sectors, delivering customized solutions that are both durable and efficient.

Our rotational moulding manufacturing facility is equipped with advanced technology that ensures precision and consistency in every product we produce. We utilize premium materials such as Polyethylene (PE), Polypropylene (PP), PVC, and Nylon to create parts with exceptional strength and longevity. These materials are carefully selected to provide superior performance, especially in environments demanding high resistance to UV exposure and elevated temperatures.

One of the key advantages of our rotational moulding production is the ability to customize wall thickness to suit specific application requirements. We offer product wall thicknesses ranging from 4mm to 8mm, enabling enhanced durability and structural integrity. This customization ensures that each product not only meets but often exceeds industry standards, providing our clients with reliable and robust components tailored to their unique needs.

The rotational molding process we employ is highly versatile, allowing for the creation of seamless, hollow parts with complex shapes and superior mechanical properties. This process involves the gradual heating and rotating of molds filled with polymer powders, resulting in uniform wall thickness and exceptional material distribution. Our mastery of this technique translates into products that deliver consistent performance and longevity, even under demanding conditions.

In addition to size and material versatility, our rotational moulding manufacturing emphasizes environmental resilience. Products manufactured through our rotational molding process exhibit outstanding UV and high-temperature resistance, making them ideal for outdoor applications and harsh operational environments. This durability ensures that products maintain their structural integrity and aesthetic appeal over extended periods, reducing maintenance costs and downtime.

Our commitment to quality and innovation in rotational moulding production is reflected in every stage of our manufacturing process. From material selection and mold design to final finishing, we adhere to rigorous quality control protocols to guarantee optimal product performance. This dedication has positioned us as a trusted partner for businesses seeking reliable rotational moulding solutions across various industries.

Whether you require small components or very large parts measuring several meters, our rotational molding process is tailored to accommodate your specifications. The flexibility inherent in rotational moulding manufacturing allows us to handle diverse project requirements, including custom shapes, sizes, and wall thicknesses. This adaptability, combined with our expertise, ensures that we can deliver products that align perfectly with your operational demands.

In summary, our rotational moulding production capabilities encompass a comprehensive range of sizes, materials, and customization options designed to provide high-performance parts with exceptional UV and high-temperature resistance. Utilizing materials such as Polyethylene, Polypropylene, PVC, and Nylon, and offering wall thicknesses from 4mm to 8mm, we deliver solutions engineered for durability and reliability. Our advanced rotational molding process and manufacturing expertise make us a preferred manufacturer for clients seeking superior rotational moulding products that stand the test of time.

Features:

-

Product Name: Rotation Moulding

-

Utilizes advanced Rotational Molding Technique for high-quality production

-

Environmental Impact: Made from recyclable materials with low waste generation

-

Color and Size: Fully customized to meet specific requirements

-

Product Wall Thickness: Customizable between 4mm and 8mm

-

Mould Material: Available in durable aluminum or steel options

-

Surface Finish: Choose between smooth or textured finishes

-

Employs state-of-the-art Rotational Moulding Manufacturing processes

-

Incorporates innovative Rotational Moulding Technology for enhanced product performance

Technical Parameters:

|

Surface Finish

|

Smooth or Textured

|

|

Material Used

|

Polyethylene (PE), Polypropylene (PP), PVC, Nylon

|

|

Product Wall Thickness

|

4mm-8mm Customized

|

|

Service

|

One-stop Service

|

|

Surface Treatment

|

Polishing, Sand Blasting, Mirror

|

|

Mould Material

|

Aluminum, Steel

|

|

Shaping Mode

|

CNC Machining

|

|

Environmental Impact

|

Recyclable Materials, Low Waste

|

|

Business Type

|

Manufacturer

|

|

Features

|

UV/High Temperature Resistance

|

Applications:

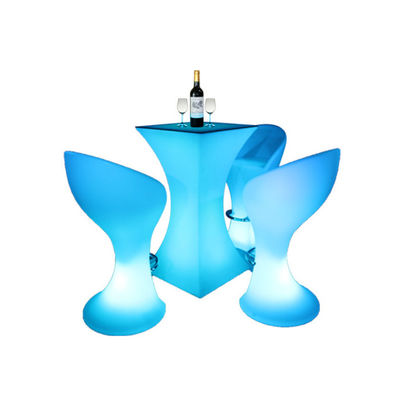

The Youge Rotation Moulding product, a Custom Model proudly manufactured in China, is designed to cater to a wide range of application occasions and scenarios. As a durable and impact-resistant solution, this product is ideal for industries requiring robust and reliable rotational plastic molding. Whether you are producing large hollow items, containers, tanks, or custom plastic components, the Youge rotational moulding manufacturing system offers exceptional performance and quality.

Thanks to its advanced rotational molding technique, this product allows for the creation of complex shapes with uniform wall thickness, making it perfect for applications in sectors such as automotive, agriculture, marine, and consumer goods. Its aluminum and steel mould materials ensure longevity and precision, while surface treatments like polishing, sand blasting, and mirror finishing provide a smooth and aesthetically pleasing surface suitable for both functional and decorative uses.

In manufacturing environments where custom orders are common, the Youge Rotation Moulding system accommodates a minimum order quantity of just one set, allowing for flexibility in production runs. The packaging, consisting of a plastic bag, cardboard box, and wooden crate, ensures safe delivery within 40-50 days, safeguarding the mould’s quality during transit. As a manufacturer, Youge offers a negotiated price to meet various budget requirements, making it accessible for businesses of different sizes.

Typical application occasions range from producing large storage tanks and playground equipment to specialized industrial parts and promotional items. The thermoplastic molding process used in rotational moulding manufacturing provides excellent mechanical properties, including impact resistance and durability, which are critical in applications exposed to harsh environmental conditions. This makes the Youge product particularly suitable for outdoor use and heavy-duty applications.

Overall, the Youge Rotation Moulding product is a versatile and efficient choice for companies looking to leverage rotational plastic molding for custom and high-quality plastic components. Its robust construction, combined with advanced rotational molding technique, ensures superior performance across diverse application scenarios, driving innovation and reliability in plastic manufacturing.

Customization:

Youge offers customized Rotation Moulding products with the model number Custom Model, proudly made in China. Our rotational moulding production supports a minimum order quantity of just 1 set, with prices available upon negotiation to fit your specific needs.

Utilizing the rotational moulding method, we specialize in thermoplastic molding processes that allow the creation of parts ranging from small to very large sizes, measuring up to several meters. Our material options include high-quality Polyethylene (PE), Polypropylene (PP), PVC, and Nylon, ensuring versatility and durability in every product.

The surface finish of our rotational molded fabrication can be tailored to your preference, offering both smooth and textured options. Packaging is carefully designed to protect your order, using plastic bags, cardboard boxes, and wooden crates as needed.

With a delivery time of 40-50 days, Youge provides a one-stop service experience, guiding you through every step of the rotational moulding production to ensure your exact specifications are met efficiently and effectively.

Support and Services:

Our Rotation Moulding product is designed to deliver high-quality, durable, and versatile solutions for a wide range of industrial applications. We provide comprehensive technical support to ensure optimal performance and customer satisfaction.

Our support services include expert guidance on material selection, mould design, processing parameters, and troubleshooting to help you achieve the best results. We also offer training sessions and detailed documentation to assist your team in mastering the rotation moulding process.

In addition, our maintenance services are aimed at maximizing the lifespan and efficiency of your equipment. Regular inspections, preventive maintenance, and timely repairs are part of our commitment to keeping your production running smoothly.

We are dedicated to continuous improvement and innovation, working closely with our clients to develop customized solutions tailored to their specific needs. Our technical support team is knowledgeable and ready to assist you in optimizing your rotation moulding operations.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped with protective materials and placed in sturdy, custom-designed cartons to prevent damage.

We use high-quality packaging materials that are both durable and environmentally friendly, ensuring the product arrives in perfect condition while minimizing environmental impact.

For shipping, we offer flexible options including air, sea, and land freight to accommodate your delivery requirements. All shipments are tracked and insured for your peace of mind.

Our logistics team works closely with trusted carriers to provide timely and reliable delivery, ensuring your rotation moulding products reach you safely and on schedule.

FAQ:

Q1: What brand manufactures this Rotation Moulding product?

A1: The Rotation Moulding product is manufactured by the brand Youge.

Q2: Can I order a custom model for the Rotation Moulding machine?

A2: Yes, Youge offers custom models for their Rotation Moulding products to meet your specific requirements.

Q3: What is the minimum order quantity for the Rotation Moulding machine?

A3: The minimum order quantity for this product is 1 set.

Q4: How long does it take to deliver the Rotation Moulding machine after placing an order?

A4: The delivery time for the Rotation Moulding machine is typically between 40 to 50 days.

Q5: How is the Rotation Moulding machine packaged for shipping?

A5: The machine is securely packaged using a plastic bag, a cardboard box, and a wooden crate to ensure safe delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!