Product Description:

Rotation Moulding is an advanced manufacturing process widely recognized for its efficiency and versatility in creating hollow, seamless products. Utilizing the Rotational Moulding Technique, this method involves heating thermoplastic materials inside a rotating mold, which ensures even distribution and fusion of the material to form durable and high-quality items. The Rotational Molded Fabrication process is especially favored in industries requiring robust and impact-resistant products with complex geometries, making it an ideal solution for a wide range of applications.

One of the primary advantages of the Rotation Moulding product is its ability to incorporate various high-performance materials such as Polyethylene (PE), Polypropylene (PP), PVC, and Nylon. These materials are carefully selected for their superior mechanical properties, including excellent durability and high impact resistance. This ensures that the final products not only meet but often exceed the stringent demands of industrial, commercial, and consumer applications. The thermoplastic molding process used in rotational molding allows for the creation of parts that can withstand significant wear and tear, making them suitable for long-term use in challenging environments.

The product’s outstanding UV and high-temperature resistance is another critical feature that enhances its suitability for outdoor and harsh environmental conditions. Exposure to sunlight and extreme temperatures often degrades lesser-quality materials, but thanks to the incorporation of UV-stabilized compounds and heat-resistant polymers, rotationally molded products maintain their structural integrity and aesthetic appeal over time. This resistance to environmental factors reduces maintenance needs and extends the lifecycle of the products, leading to cost savings and improved performance in demanding applications.

Our Rotation Moulding offering is backed by a comprehensive one-stop service approach, which streamlines the entire production cycle from design and prototyping to manufacturing and delivery. This integrated service model ensures that clients receive tailored solutions that precisely match their specifications and performance requirements. By leveraging the Rotational Moulding Method, we provide custom fabrication capabilities that accommodate a wide array of shapes, sizes, and wall thicknesses, all while maintaining consistent quality and efficiency.

The Rotational Molding Technique also offers significant design flexibility compared to other thermoplastic molding methods. Because the material coats the entire interior surface of the mold evenly, it is possible to produce complex hollow shapes without the need for assembly or welding. This seamless construction not only improves the mechanical strength of the product but also eliminates potential leak points and weak spots, enhancing overall reliability. Additionally, the ability to use multiple materials and colors in a single molding cycle expands the aesthetic and functional possibilities for product designers.

In terms of environmental impact, the Rotation Moulding process is relatively low-waste, as excess material can often be recycled and reused in subsequent cycles. The use of thermoplastic materials such as PE, PP, PVC, and Nylon further supports sustainability efforts due to their recyclability and long service life. This combination of eco-friendly practices and robust product attributes aligns well with contemporary industry trends focused on reducing environmental footprint without sacrificing quality or performance.

To summarize, the Rotation Moulding product stands out as a superior choice for manufacturers and end-users seeking durable, impact-resistant, and UV/high temperature resistant solutions. By harnessing the benefits of the Rotational Moulding Method and Thermoplastic Molding processes, this product delivers exceptional mechanical properties and design versatility. Supported by a one-stop service framework, it enables efficient, cost-effective, and customized production tailored to diverse industrial needs. Whether for storage tanks, automotive components, industrial containers, or consumer goods, rotationally molded products consistently demonstrate reliability, longevity, and performance excellence.

Features:

-

Product Name: Rotation Moulding

-

Process Type: Thermoplastic Molding using Rotational Moulding Technology

-

Mould Material: High-quality Aluminum and Steel

-

Surface Finish: Smooth or Textured options available

-

Color and Size: Fully Customized to meet specific requirements

-

Product Wall Thickness: Adjustable between 4mm and 8mm as per customization

-

Manufactured through advanced Rotational Molded Fabrication techniques

-

Utilizes the precise Rotational Moulding Method for durable and consistent products

Technical Parameters:

|

Environmental Impact

|

Recyclable Materials, Low Waste

|

|

Product Wall Thickness

|

4mm-8mm Customized

|

|

Product Size Range

|

Small To Very Large Parts (up To Several Meters)

|

|

Process Type

|

Thermoplastic Molding

|

|

Surface Finish

|

Smooth Or Textured

|

|

Service

|

One-stop Service

|

|

Color And Size

|

Customized

|

|

Business Type

|

Manufacturer

|

|

Material Used

|

Polyethylene (PE), Polypropylene (PP), PVC, Nylon

|

|

Mould Material

|

Aluminum, Steel

|

Applications:

The Youge Rotation Moulding product, identified by its Custom Model number and manufactured in China, is designed for a wide range of application occasions and scenarios due to its versatile and robust features. Utilizing the advanced Rotational Moulding Manufacturing process, this product benefits from the Rotational Casting Process, which ensures uniform wall thickness ranging from 4mm to 8mm, customizable to meet specific requirements. This flexibility allows it to cater to small components as well as very large parts, extending up to several meters in size, making it suitable for diverse industrial and commercial uses.

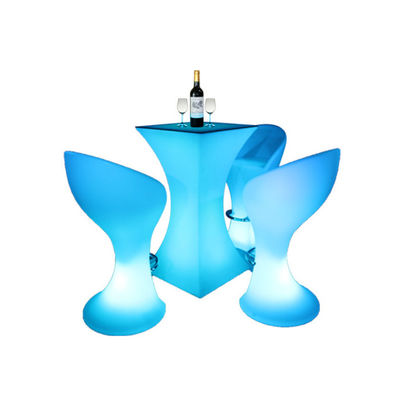

Thanks to the innovative Rotational Molding Technique, the Youge product exhibits exceptional mechanical properties including high durability and impact resistance. These characteristics make it ideal for demanding environments where toughness and longevity are essential. The product’s UV and high-temperature resistance further expand its usability, enabling it to withstand harsh outdoor conditions and extreme climates without degradation, which is crucial in many sectors such as agriculture, automotive, construction, and outdoor furniture manufacturing.

In industrial settings, the Youge rotation moulded products are widely used for manufacturing large storage tanks, containers, and protective casings that require consistent wall strength and resistance to corrosion and environmental stress. Their capacity to be customized in size and thickness makes them perfect for tailor-made solutions in chemical storage, water treatment facilities, and even playground equipment that must comply with stringent safety standards.

Moreover, the product is suitable for small-scale applications such as custom packaging, promotional items, and specialized technical parts that benefit from the precise control offered by the Rotational Casting Process. The minimum order quantity of just one set, combined with a negotiated price, offers flexibility for businesses of all sizes, from startups requiring prototypes to large manufacturers needing bulk production.

Packaging is thoughtfully designed with a combination of plastic bags, cardboard boxes, and wooden crates to ensure safe delivery within 40-50 days. As a manufacturer, Youge emphasizes quality assurance and customer satisfaction, making their rotational molding products a reliable choice across various industries. Whether for industrial manufacturing, commercial applications, or specialized custom projects, the Youge Rotation Moulding product adapts seamlessly to diverse operational scenarios, leveraging the strengths of the rotational molding technique to deliver superior performance.

Customization:

Youge offers top-quality Rotation Moulding products with a customizable model tailored to your needs. Our Custom Model is manufactured in China, ensuring excellent craftsmanship and reliability.

With a minimum order quantity of just 1 set, we provide flexible solutions for both small and large scale projects. Pricing is negotiable to accommodate your specific requirements.

Our Rotation Moulding Production utilizes advanced thermoplastic molding processes to deliver durable and impact-resistant products. We specialize in Rotational Plastic Molding and Rotational Molded Fabrication, ensuring high performance and longevity.

Surface treatments such as polishing, sand blasting, and mirror finishing are available to enhance the aesthetic and functional qualities of your product.

We prioritize environmental responsibility by using recyclable materials and minimizing waste during production, aligning with sustainable manufacturing practices.

Colors and sizes are fully customizable to match your design specifications. Each product is carefully packaged using plastic bags, cardboard boxes, and wooden materials to guarantee safe delivery.

Delivery time ranges from 40 to 50 days, ensuring timely fulfillment of your orders with consistent quality.

Support and Services:

Our Rotation Moulding product is backed by comprehensive technical support and services designed to ensure optimal performance and customer satisfaction. We provide expert guidance on material selection, mold design, and processing parameters to help you achieve the best results.

Our team of specialists offers troubleshooting assistance and preventive maintenance tips to minimize downtime and extend the life of your equipment. We also provide training programs tailored to your staff’s needs to enhance operational efficiency and product quality.

Additionally, we offer custom solutions and upgrades to meet evolving production requirements. Whether you need help with installation, calibration, or process optimization, our dedicated support team is ready to assist you every step of the way.

Trust our Rotation Moulding technical support and services to maximize your production capabilities and maintain the highest standards of quality.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped with protective materials to prevent damage and is placed in sturdy, custom-fit boxes designed to withstand handling and shipping stresses.

We partner with reliable logistics providers to offer timely and safe delivery worldwide. Shipping options include standard, expedited, and freight services, tailored to meet your specific needs. Tracking information will be provided upon dispatch to keep you informed throughout the shipping process.

For bulk orders, we offer palletized shipping to optimize space and safeguard products during transportation. Please contact our customer service team for special packaging requests or to discuss customized shipping solutions.

FAQ:

Q1: What is the brand and model number of this rotation moulding product?

A1: The brand name is Youge, and the product comes in a Custom Model tailored to your specific needs.

Q2: Where is this rotation moulding product manufactured?

A2: This product is made in China.

Q3: What is the minimum order quantity for this rotation moulding product?

A3: The minimum order quantity is 1 set.

Q4: How is the product packaged for delivery?

A4: The product is packaged securely using a plastic bag, cardboard box, and wooden packaging to ensure safe shipment.

Q5: What is the typical delivery time for this rotation moulding product?

A5: The delivery time usually ranges from 40 to 50 days after order confirmation.

Q6: How is the price determined for this rotation moulding product?

A6: The price is negotiable and will be determined based on your specific requirements and order details.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!