Product Description:

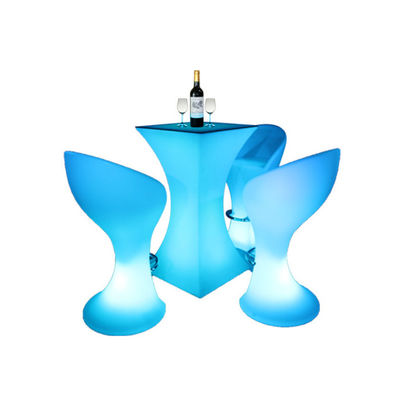

Our Rotation Moulding product represents the pinnacle of innovation and precision in the field of rotational moulding technology. Utilizing advanced CNC machining as the shaping mode, this product delivers unparalleled accuracy and consistency, ensuring that each piece meets the highest standards of quality. As a manufacturer dedicated to excellence, we provide customized solutions tailored to meet the specific needs of our clients, allowing for variations in color, size, and wall thickness to perfectly align with unique project requirements.

The rotational moulding process employed in the production of this product is a highly efficient and versatile manufacturing technique. It involves heating the raw material inside a mold that rotates biaxially, ensuring even distribution and forming a seamless, hollow part with uniform wall thickness. This method allows for the creation of complex shapes and large-sized components that are difficult or impossible to manufacture using other processes. Our expertise in rotational moulding production guarantees that every product not only meets but exceeds industry standards in durability and performance.

One of the standout features of our rotation moulding product is its customizable product wall thickness, ranging from 4mm to 8mm. This flexibility allows for optimization based on the intended application, balancing strength, weight, and material usage effectively. Whether the requirement is for lightweight parts or robust, heavy-duty components, our rotational moulding technology adapts seamlessly to deliver superior results. Additionally, the ability to customize color and size further enhances the product's versatility, making it suitable for an extensive range of industries, including automotive, agriculture, storage, and outdoor equipment.

Durability and resilience are at the core of this product’s design. It boasts exceptional UV and high-temperature resistance, making it ideal for outdoor applications exposed to harsh environmental conditions. The UV resistance ensures that the product maintains its color and structural integrity even after prolonged exposure to sunlight, preventing degradation and extending its service life. High-temperature resistance adds another layer of reliability, allowing the product to perform consistently in environments with fluctuating or elevated temperatures without warping or losing strength.

As a manufacturer deeply invested in rotational moulding production, we leverage state-of-the-art technology and rigorous quality control processes to deliver products that meet the most demanding specifications. Our rotational moulding process not only enhances the product’s mechanical properties but also ensures an eco-friendly production cycle with minimal waste, as excess material can often be recycled. This commitment to sustainability, combined with superior product performance, positions our rotation moulding products as a preferred choice for clients seeking reliable and efficient manufacturing solutions.

In summary, our Rotation Moulding product, crafted through sophisticated rotational moulding technology and CNC machining shaping mode, offers customized color and size options, with a product wall thickness tailored between 4mm and 8mm. As a reputable manufacturer, we prioritize features such as UV and high-temperature resistance, ensuring that the final products are robust, long-lasting, and perfectly suited to their applications. Whether you require complex shapes or durable outdoor components, our rotational moulding production capabilities provide the flexibility and quality needed to meet your exact specifications, making us an ideal partner in your manufacturing endeavors.

Features:

-

Product Name: Rotation Moulding

-

Color and Size: Customized to meet specific requirements

-

Material Used: Polyethylene (PE), Polypropylene (PP), PVC, Nylon

-

Mechanical Properties: Durable and Impact Resistant

-

Surface Finish: Available in Smooth or Textured options

-

Surface Treatment: Polishing, Sand Blasting, Mirror finishing

-

Utilizes advanced Rotational Moulding Technology for high-quality results

-

Employs the Rotational Molding Process to ensure uniform material distribution

-

Expertise in Rotational Molded Fabrication for customized and precise products

Technical Parameters:

|

Features

|

UV/High Temperature Resistance

|

|

Material

|

Aluminum

|

|

Product Wall Thickness

|

4mm-8mm Customized

|

|

Product Size Range

|

Small To Very Large Parts (up To Several Meters)

|

|

Color And Size

|

Customized

|

|

Service

|

One-stop Service

|

|

Shaping Mode

|

CNC Machining

|

|

Surface Treatment

|

Polishing, Sand Blasting, Mirror

|

|

Mechanical Properties

|

Durable, Impact Resistant

|

|

Mould Material

|

Aluminum, Steel

|

Applications:

The Youge Rotation Moulding product, Custom Model, originating from China, is designed to cater to a wide range of application occasions and scenarios due to its versatile and robust features. Utilizing the advanced Rotational Moulding Method, this product is ideal for manufacturing small to very large parts, some reaching up to several meters in size. Its ability to produce complex shapes with uniform wall thickness makes it highly suitable for industries requiring durable and lightweight components.

The Rotational Moulding Process employed by Youge ensures high precision and excellent quality, with mould materials available in aluminum and steel to accommodate various production needs. This method is especially beneficial for creating products that demand UV and high temperature resistance, making it perfect for outdoor applications such as storage tanks, playground equipment, automotive parts, and agricultural containers. The customizable color and size options further enhance its adaptability to different design requirements and branding needs.

Because the product is made from recyclable materials and emphasizes low waste during production, it aligns well with environmentally conscious manufacturing practices. This makes it an excellent choice for companies aiming to reduce their ecological footprint while still producing durable and reliable products. The packaging, consisting of a plastic bag, cardboard box, and wooden crate, ensures safe delivery, which typically takes between 40 to 50 days after order confirmation.

The minimum order quantity of just 1 set with a negotiated price provides flexibility for both small-scale and large-scale manufacturers. Whether used in industrial applications, consumer goods, or specialized sectors, the Youge Rotation Moulding product offers a sustainable, high-performance solution. Its reliable Rotational Moulding Method enables the production of parts that withstand harsh environmental conditions, making it suitable for marine, construction, and chemical storage applications as well.

In summary, the Youge Rotation Moulding product is perfectly suited for a variety of scenarios including outdoor equipment, industrial containers, automotive parts, and custom large-scale designs. Thanks to its customizable features, environmentally friendly materials, and the precision of the Rotational Moulding Process, it meets the diverse needs of modern manufacturing with efficiency and sustainability.

Customization:

Our Youge brand offers customized Rotation Moulding products under the Custom Model, proudly made in China. We specialize in Rotational Moulding Manufacturing, providing tailored solutions with a minimum order quantity of just 1 set, ensuring flexibility for all project sizes.

We utilize high-quality aluminum and steel mould materials, crafted through advanced CNC machining shaping modes. Our product size range covers everything from small parts to very large components measuring up to several meters, catering to diverse industry needs.

Our Rotational Molded Fabrication process includes meticulous surface treatments such as polishing, sand blasting, and mirror finishing, delivering superior aesthetics and performance. The products are designed to feature UV and high temperature resistance, ensuring durability in demanding environments.

Packaging is handled with care, using plastic bags, cardboard boxes, and wooden crates to guarantee safe delivery. The typical delivery time ranges from 40 to 50 days, with pricing available through negotiation to best fit your requirements.

Trust our expertise in the rotational casting process to deliver high-quality, customized rotational moulding products that meet your exact specifications and industry standards.

Support and Services:

Our Rotation Moulding product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We offer expert guidance on product selection, design considerations, and process optimization to help you achieve the best results.

Our technical support team is available to assist with troubleshooting, maintenance advice, and operational training. We provide detailed documentation, including user manuals and technical datasheets, to support your understanding and effective use of the product.

Additionally, we offer customized solutions and after-sales services to address specific needs and challenges. Our goal is to help you maximize the efficiency and longevity of your rotation moulding equipment through reliable and responsive support.

For ongoing assistance, we recommend regular maintenance checks and updates based on the latest industry standards and technological advancements. Our commitment is to provide you with the highest level of service throughout the lifecycle of your rotation moulding product.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped using high-quality materials to prevent any damage, including bubble wrap and sturdy cardboard boxes tailored to the product's dimensions.

For shipping, we partner with reliable carriers to guarantee timely and safe delivery. Products are handled with care throughout the shipping process, and tracking information is provided to keep you informed every step of the way.

Whether shipping locally or internationally, we comply with all packaging and shipping regulations to ensure your rotation moulding products arrive in perfect condition.

FAQ:

Q1: What is the brand name of the Rotation Moulding product?

A1: The brand name of the Rotation Moulding product is Youge.

Q2: Can I order a custom model for the Rotation Moulding machine?

A2: Yes, the model number is Custom Model, and we can accommodate custom specifications based on your requirements.

Q3: What is the minimum order quantity for the Rotation Moulding product?

A3: The minimum order quantity is 1 set.

Q4: How is the Rotation Moulding product packaged for delivery?

A4: The product is carefully packaged using a plastic bag, cardboard box, and wooden packaging to ensure safe transportation.

Q5: What is the typical delivery time after placing an order?

A5: The delivery time is usually between 40 to 50 days after order confirmation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!