Product Description:

The Rotation Moulding product is a highly versatile and efficient solution designed to meet diverse industrial and commercial needs through the advanced Rotational Moulding Method. Utilizing the innovative rotational plastic molding technology, this product is crafted with precision and care to deliver superior quality and performance. The shaping mode employed in the manufacturing process is CNC Machining, which ensures exceptional accuracy and consistency in the final product dimensions and design.

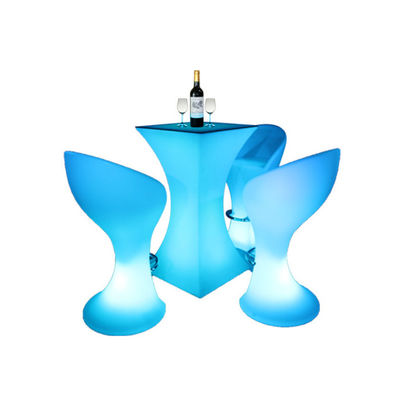

One of the standout features of this Rotation Moulding product is its customization capability. Both color and size can be tailored to meet specific client requirements, allowing for a wide range of applications across different sectors. Whether you need vibrant, eye-catching colors or subtle, professional tones, the customization options provide flexibility to suit branding and functional demands. Additionally, the size customization ensures that the product can be adapted to fit various operational environments and spatial constraints.

The manufacturing process is based on the thermoplastic molding technique, which is known for its ability to produce durable and robust products. The thermoplastic molding process used in rotational molding allows the material to be evenly heated and molded into complex shapes without compromising structural integrity. This leads to the creation of products that are not only visually appealing but also mechanically superior.

Material selection plays a crucial role in the performance of the Rotation Moulding product. High-quality thermoplastic materials such as Polyethylene (PE), Polypropylene (PP), PVC, and Nylon are used, each chosen for their unique properties and advantages. Polyethylene offers excellent chemical resistance and toughness, making it ideal for applications requiring durability. Polypropylene provides a good balance of strength and flexibility, while PVC is valued for its rigidity and weather resistance. Nylon contributes enhanced impact resistance and mechanical strength, making the product suitable for demanding environments.

In terms of mechanical properties, this product excels in durability and impact resistance. These attributes are essential for ensuring long service life and reliable performance, especially in applications subjected to rough handling or harsh conditions. The robust nature of the product, achieved through the rotational molding process, enables it to withstand physical stresses without cracking or deforming, which is a common challenge in other molding methods.

The rotational molding process itself is a key factor in the product’s superior quality. By rotating the mold biaxially during the heating phase, the material coats the interior surface evenly, resulting in uniform wall thickness and minimal material waste. This method also allows for the creation of hollow, seamless shapes that are lightweight yet strong. The rotational plastic molding technique is cost-effective and environmentally friendly, as it reduces scrap and enables the use of recycled materials without compromising product performance.

Furthermore, the Rotation Moulding product benefits from the precision of CNC Machining, which enhances the overall finish and functional features. CNC Machining ensures that every component meets exact specifications, providing excellent fitting and assembly capabilities. This combination of rotational molding and CNC machining results in products that are not only structurally sound but also aesthetically refined.

In summary, the Rotation Moulding product manufactured through the rotational molding process using the rotational plastic molding technique represents a pinnacle of innovation in thermoplastic molding. With customizable color and size options, durable and impact-resistant mechanical properties, and a selection of high-performance materials such as Polyethylene, Polypropylene, PVC, and Nylon, this product is engineered to deliver outstanding results in a wide array of applications. The integration of CNC Machining further elevates the product’s precision and quality, making it a reliable choice for industries seeking dependable and adaptable molded solutions.

Features:

-

Product Name: Rotation Moulding

-

Material: Aluminum

-

Material Used: Polyethylene (PE), Polypropylene (PP), PVC, Nylon

-

Environmental Impact: Recyclable Materials, Low Waste

-

Surface Treatment Options: Polishing, Sand Blasting, Mirror Finish

-

Features: UV Resistance, High Temperature Resistance

-

Manufactured using advanced Rotational Molding Technique

-

Utilizes the Rotational Casting Process for uniform thickness and durability

-

Employs the Rotational Molding Technique to produce high-quality, robust products

Technical Parameters:

|

Environmental Impact

|

Recyclable Materials, Low Waste

|

|

Product Wall Thickness

|

4mm-8mm Customized

|

|

Material

|

Aluminum

|

|

Business Type

|

Manufacturer

|

|

Color And Size

|

Customized

|

|

Surface Treatment

|

Polishing, Sand Blasting, Mirror

|

|

Process Type

|

Thermoplastic Molding (Rotational Moulding Technology)

|

|

Features

|

UV/High Temperature Resistance

|

|

Mould Material

|

Aluminum, Steel

|

|

Shaping Mode

|

CNC Machining (Rotational Moulding Method)

|

|

Additional Note

|

Utilizes advanced Rotational Polymer Moulding for superior product quality

|

Applications:

The Youge Rotation Moulding product, identified by the Custom Model from China, is an advanced solution designed for a wide range of applications across various industries. Utilizing the Thermoplastic Molding process, this product excels in producing Small to Very Large Parts, reaching dimensions of up to several meters, making it highly versatile for diverse manufacturing needs. With a minimum order quantity of just 1 set and a negotiated price, it offers flexibility and accessibility for businesses of all sizes seeking high-quality rotational polymer moulding solutions.

One of the most significant advantages of Youge's rotational moulding manufacturing is its ability to create durable, UV and high-temperature resistant components. This feature makes it ideal for outdoor applications where exposure to harsh environmental conditions is common. The recyclable materials and low waste production process ensure that the rotational casting process aligns with sustainable manufacturing practices, appealing to environmentally conscious companies looking to reduce their ecological footprint.

The product's packaging, which includes a plastic bag, cardboard box, and wooden protection, guarantees safe delivery within a 40-50 day timeframe. This careful packaging and timely delivery are crucial for industries that rely on punctual and secure shipment of their components. Furthermore, Youge provides a one-stop service that streamlines the entire manufacturing journey, from design to finished product, enhancing efficiency and customer satisfaction.

In terms of application occasions and scenarios, Youge’s rotational polymer moulding is perfectly suited for outdoor furniture, large storage tanks, automotive parts, playground equipment, and industrial containers. Its capability to produce large-scale parts through the rotational casting process means it can serve sectors such as agriculture, construction, and marine industries where robust and weather-resistant components are essential. Additionally, the process is ideal for creating customized products tailored to specific client needs, ensuring versatility in usage.

Given its features and manufacturing excellence, the Youge Rotation Moulding product is indispensable for businesses seeking reliable, eco-friendly, and high-performance solutions in rotational moulding manufacturing. Whether it’s small-scale prototypes or very large functional parts, this product meets a broad spectrum of application occasions and scenarios with exceptional quality and environmental responsibility.

Customization:

Our Rotation Moulding product by Youge is designed for superior performance and customization. Featuring a Custom Model and manufactured in China, this product is tailored to meet your specific needs with a minimum order quantity of just 1 set. The price is negotiable to provide the best value for your investment.

We utilize the advanced Rotational Molding Process combined with CNC Machining shaping mode to ensure precision and durability in every piece. Made from high-quality aluminum material, our product offers excellent UV and high temperature resistance, making it ideal for various demanding applications.

As a reputable manufacturer, Youge provides superior packaging including plastic bag, cardboard box, and wooden packaging to ensure safe delivery. The delivery time is typically 40-50 days, allowing for efficient production and shipping schedules.

Our expertise in the Rotational Molding Process and Rotational Molded Fabrication guarantees a thermoplastic molding product that meets your exact specifications and quality standards.

Support and Services:

Our Rotation Moulding products come with comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide expert guidance on material selection, design considerations, and processing parameters to help you achieve the best results. Our technical team is available to assist with troubleshooting, maintenance advice, and process optimization. Additionally, we offer training sessions and detailed documentation to support your manufacturing needs. Whether you are new to rotation moulding or looking to improve your existing processes, our dedicated support services are here to help you succeed.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped with protective materials to prevent damage from impact, moisture, and dust. The products are then placed in sturdy, custom-sized cartons or crates designed to withstand rough handling and stacking.

For shipping, we use reliable logistics partners who specialize in handling large and heavy items. Depending on the destination and order size, products may be shipped via sea freight, air freight, or road transport. All shipments are tracked and insured to guarantee safe and timely delivery to our customers worldwide.

We also offer tailored packaging solutions upon request, including palletization and shrink-wrapping, to meet specific client requirements. Our commitment to quality packaging and secure shipping ensures that your rotation moulding products arrive in perfect condition, ready for immediate use.

FAQ:

Q1: What is the brand name of the Rotation Moulding product?

A1: The Rotation Moulding product is branded as Youge.

Q2: Can I order a custom model for the Rotation Moulding machine?

A2: Yes, Youge offers custom models to meet your specific requirements.

Q3: What is the minimum order quantity for this product?

A3: The minimum order quantity for the Rotation Moulding machine is 1 set.

Q4: How long does it take to deliver the Rotation Moulding product?

A4: The typical delivery time for the product is between 40 to 50 days.

Q5: How is the Rotation Moulding product packaged for shipment?

A5: The product is carefully packaged using a plastic bag, cardboard box, and wooden crate to ensure safe delivery.

Q6: Where is the Rotation Moulding machine manufactured?

A6: The Rotation Moulding machine is manufactured in China.

Q7: Is the price fixed for the Rotation Moulding machine?

A7: The price is negotiable depending on the customization and order details.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!