Product Description:

The Rotation Moulding product is a high-quality solution designed to meet diverse industrial and commercial needs through advanced manufacturing techniques. Utilizing the Rotational Moulding Method, this product offers exceptional durability, versatility, and precision. This innovative process allows for the creation of seamless, hollow parts with uniform wall thickness and excellent structural integrity, making it ideal for a wide range of applications.

One of the most critical features of this Rotation Moulding product is its customizable wall thickness, which ranges from 4mm to 8mm. This flexibility in thickness ensures that the product can be tailored to meet specific strength and weight requirements, enhancing its performance and longevity. Whether you need a lightweight component or a robust, heavy-duty part, the customizable wall thickness makes this product adaptable to various demands.

The surface finish of the product can be either smooth or textured, depending on the application and aesthetic preferences. A smooth surface finish provides a sleek, polished look and is easier to clean, making it suitable for consumer-facing products or environments that require hygiene and easy maintenance. On the other hand, a textured surface finish offers enhanced grip, reduced glare, and a distinctive appearance, which is beneficial for industrial or outdoor applications where functionality and durability are paramount.

The molds used in the production of this Rotation Moulding product are crafted from high-quality aluminum and steel. Aluminum molds are known for their excellent heat conductivity, which results in shorter cycle times and increased production efficiency. They are lightweight and offer good durability, making them suitable for complex designs and multiple production runs. Steel molds, meanwhile, provide superior strength and wear resistance, ideal for large-scale manufacturing where longevity and precision are critical. The choice between aluminum and steel molds allows for flexibility in production, balancing cost, durability, and performance based on specific project requirements.

The core manufacturing process employed is thermoplastic molding, a technique that involves heating plastic material until it becomes pliable, then shaping it within the mold as it rotates simultaneously around two perpendicular axes. This Rotational Plastic Molding process ensures even distribution of the material along the mold walls, resulting in consistent thickness and high-quality finished products. Thermoplastic molding is renowned for its ability to produce complex shapes without the need for additional assembly, reducing production time and costs while enhancing product reliability.

Material selection is a vital aspect of this product, with aluminum being a key material used in the molds to optimize the rotational molding process. Aluminum's excellent thermal properties contribute to efficient heating and cooling cycles, improving overall production speed and product quality. Furthermore, the use of aluminum and steel in the mold construction ensures that the molds withstand the high temperatures and mechanical stresses involved in the rotational molding process, guaranteeing long-term performance and consistent output.

The Rotational Moulding Method employed in this product’s manufacturing offers several advantages over traditional molding techniques. It enables the production of large, hollow parts without seams, reducing the risk of leaks or weak points. The ability to produce complex geometries with uniform wall thickness enhances the functional and aesthetic qualities of the product. Moreover, the rotational plastic molding technique is cost-effective, especially for low to medium production volumes, as it requires lower tooling costs compared to other molding methods.

In summary, the Rotation Moulding product is a versatile and reliable choice for industries requiring robust, customizable, and high-quality molded components. Its customizable wall thickness from 4mm to 8mm, choice of smooth or textured surface finishes, and the use of durable aluminum and steel molds highlight its adaptability and superior manufacturing standards. Leveraging the Rotational Moulding Method and thermoplastic molding process, this product delivers consistent, high-performance results suitable for a broad spectrum of applications. Whether for industrial, commercial, or consumer uses, this product exemplifies the benefits of rotational plastic molding in producing durable, precise, and cost-effective molded parts.

Features:

-

Product Name: Rotation Moulding

-

Material Used: Polyethylene (PE), Polypropylene (PP), PVC, Nylon

-

Mould Material: Aluminum, Steel

-

Process Type: Thermoplastic Molding

-

Product Wall Thickness: 4mm-8mm Customized

-

Service: One-stop Service

-

Utilizes advanced Rotational Moulding Production techniques

-

High-quality Rotational Moulding Production ensuring durability and precision

-

Efficient Rotational Molding Process for consistent product quality

Technical Parameters:

|

Material Used

|

Polyethylene (PE), Polypropylene (PP), PVC, Nylon

|

|

Mould Material

|

Aluminum, Steel

|

|

Environmental Impact

|

Recyclable Materials, Low Waste

|

|

Features

|

UV/High Temperature Resistance

|

|

Shaping Mode

|

CNC Machining

|

|

Business Type

|

Manufacturer

|

|

Material

|

Aluminum

|

|

Color And Size

|

Customized

|

|

Surface Finish

|

Smooth Or Textured

|

|

Surface Treatment

|

Polishing, Sand Blasting, Mirror

|

Applications:

The Youge Rotation Moulding product, model Custom Model, originating from China, is designed to cater to a wide range of application occasions and scenarios, making it an ideal choice for various industries. With a minimum order quantity of just 1 set and a negotiated price, this product offers flexibility and accessibility for both small-scale and large-scale projects.

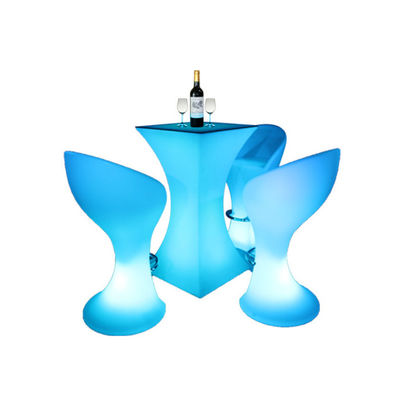

Rotational Polymer Moulding is widely used in the manufacturing of hollow and complex shapes, which are otherwise difficult to produce through conventional methods. The Youge product excels in delivering high-quality rotational moulding manufacturing solutions, utilizing advanced CNC machining shaping modes to ensure precision and consistency. This makes it perfectly suited for producing items such as large tanks, containers, automotive parts, playground equipment, and furniture, among others.

One of the key attributes of this rotational moulding manufacturing product is its environmental impact. It employs recyclable materials and generates low waste during production, aligning with sustainable manufacturing practices. This makes it a preferred choice for businesses and manufacturers committed to reducing their ecological footprint while maintaining product durability and performance.

The surface treatment options available, including polishing, sand blasting, and mirror finishing, provide versatility in aesthetics and functionality. These finishes enhance the appearance and durability of the final product, making it suitable for both industrial and consumer applications that require a professional and appealing look.

Mechanical properties such as durability and impact resistance are critical for products manufactured through rotational polymer moulding. The Youge rotation moulding product is engineered to withstand harsh conditions and heavy usage, ensuring long service life and reliability in demanding environments. This makes it ideal for outdoor equipment, industrial containers, and other applications where strength and resilience are paramount.

Packaging details comprising plastic bags, cardboard boxes, and wooden crates ensure that each unit is securely packed for safe delivery. With a delivery time of 40-50 days and comprehensive one-stop service support, customers receive not just a product but an end-to-end solution from order to delivery.

In summary, the Youge Rotation Moulding product is perfect for diverse rotational polymer moulding applications, offering environmental benefits, superior mechanical properties, and customizable surface treatments. Its adaptability across various scenarios and industries makes it a valuable asset in the rotational moulding manufacturing sector.

Customization:

The Youge Rotation Moulding product, model Custom Model, is crafted through an advanced Rotational Casting Process that ensures high durability and impact resistance. Originating from China, this product is made from premium aluminum material, providing exceptional mechanical properties suitable for various applications.

We offer full customization options including product wall thickness ranging from 4mm to 8mm, color, and size to meet your specific needs. The surface finish can be tailored to be either smooth or textured, enhancing both aesthetics and functionality. Our Rotational Plastic Molding technique guarantees consistent quality and precision in every unit.

With a minimum order quantity of just 1 set and a negotiated price, we make it easy to get started with your custom project. Packaging is securely done using a plastic bag, cardboard box, and wooden crates to ensure safe delivery. The typical delivery time is between 40 to 50 days.

Choose Youge for your rotational casting needs and experience superior product customization services that leverage the best of the Rotational Casting Process.

Support and Services:

Our Rotation Moulding technical support team is dedicated to providing comprehensive assistance to ensure optimal performance and longevity of your products. We offer expert guidance on mold design, material selection, and process optimization to help you achieve the best results in your manufacturing operations.

Our services include troubleshooting support, maintenance advice, and training sessions tailored to your specific needs. Whether you are facing challenges in cycle times, material flow, or product consistency, our specialists are here to help you identify and resolve issues efficiently.

Additionally, we provide consultation on upgrading existing equipment and implementing the latest technologies in rotation moulding to enhance productivity and reduce operational costs. Our goal is to support your business with reliable solutions and continuous improvement strategies.

For any technical inquiries or service requests, please refer to our support guidelines and documentation to facilitate a prompt and effective response from our team.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped with protective materials and placed in sturdy, custom-designed cartons to prevent damage.

For shipping, we offer flexible options including sea freight, air freight, and road transport to meet your delivery needs. All shipments are handled with care and tracked to guarantee timely and safe arrival at your destination.

We prioritize efficient packaging and reliable shipping methods to provide you with high-quality rotation moulding products delivered in perfect condition.

FAQ:

Q1: What is the brand name of the Rotation Moulding product?

A1: The Rotation Moulding product is branded as Youge.

Q2: Can I order a custom model for the Rotation Moulding machine?

A2: Yes, Youge offers custom models to meet your specific requirements.

Q3: What is the minimum order quantity for the Rotation Moulding product?

A3: The minimum order quantity is 1 set.

Q4: How long is the delivery time for the Rotation Moulding machine?

A4: The delivery time is typically between 40 to 50 days.

Q5: How is the Rotation Moulding product packaged for shipment?

A5: The product is carefully packaged using a plastic bag, cardboard box, and wooden crate to ensure safe delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!