Product Description:

The rotational molding product offers a versatile and efficient solution for manufacturing plastic parts with a wide range of applications. Utilizing the advanced rotational molding technique, this product is designed to meet diverse industry needs by providing customizable options in surface finish, color, size, and environmental sustainability. The rotational molding process employed ensures high-quality output, making it ideal for producing small to very large parts, some reaching several meters in size, without compromising on precision or durability.

One of the standout features of this rotational molding product is the flexibility in surface finish. Customers can choose between a smooth or textured surface, depending on their aesthetic and functional requirements. This adaptability is further enhanced by various surface treatment options available, including polishing, sand blasting, and mirror finishing. These treatments not only improve the visual appeal but also contribute to the product’s performance by enhancing surface properties such as resistance to wear and ease of cleaning.

Customization is a core advantage of this product. The rotational molding process allows for a vast spectrum of colors and sizes to be tailored to specific project needs. Whether the application demands vibrant, eye-catching colors or subtle, professional tones, the product can be customized to match exact specifications. Additionally, the size range supported by this product is impressive, accommodating everything from small intricate parts to very large components measuring several meters. This scalability makes the rotational molding technique particularly valuable for industries ranging from automotive and aerospace to outdoor furniture and storage tanks.

Environmental considerations are increasingly important in manufacturing, and this rotational molding product addresses these concerns effectively. Made from recyclable materials, it supports sustainability by reducing the environmental footprint typically associated with plastic production. Moreover, the rotational molding process itself is known for generating low waste compared to other manufacturing techniques. This efficiency stems from the precise control of material usage and minimal scrap generation, making it an eco-friendly choice that aligns with modern green manufacturing standards.

The rotational molding process involves heating a mold filled with powdered resin while it rotates biaxially. This ensures even distribution of the material along the interior walls of the mold, resulting in consistent wall thickness and structural integrity. The process is highly adaptable, allowing for the production of complex shapes and hollow parts that would be difficult or impossible to achieve with other molding methods. This adaptability, combined with the product’s customizable attributes and environmental benefits, makes it a preferred choice for manufacturers looking to innovate while maintaining quality and sustainability.

In summary, this rotational molding product delivers a perfect blend of customization, quality, and environmental responsibility. Its smooth or textured surface finishes, enhanced by polishing, sand blasting, or mirror treatments, offer aesthetic and functional versatility. The ability to customize color and size, from small parts to very large components, ensures it meets the demands of various industries. Additionally, the use of recyclable materials and the low waste nature of the rotational molding process underline the product’s commitment to sustainable manufacturing practices. Whether for industrial applications, consumer goods, or specialized equipment, this rotational molding product stands out as a reliable and eco-conscious choice that leverages the full potential of the rotational molding technique.

Features:

-

Product Name: Rotation Moulding

-

Surface Finish: Smooth or Textured options available

-

Material: High-quality Aluminum components

-

Materials Used: Polyethylene (PE), Polypropylene (PP), PVC, Nylon

-

Environmental Impact: Made from recyclable materials with low waste production

-

Service: Comprehensive one-stop service for all your needs

-

Utilizes the advanced Rotational Molding Process for superior product quality

-

Efficient Rotational Polymer Moulding technique ensures durability and precision

-

Expertise in the Rotational Molding Process guarantees consistent and reliable results

Technical Parameters:

|

Material

|

Aluminum

|

|

Surface Finish

|

Smooth or Textured

|

|

Features

|

UV/High Temperature Resistance

|

|

Shaping Mode

|

CNC Machining

|

|

Process Type

|

Thermoplastic Molding

|

|

Mould Material

|

Aluminum, Steel

|

|

Service

|

One-stop Service

|

|

Product Size Range

|

Small to Very Large Parts (up to Several Meters)

|

|

Color and Size

|

Customized

|

|

Mechanical Properties

|

Durable, Impact Resistant

|

Applications:

The Youge Rotation Moulding product, featuring the Custom Model from China, is designed to cater to a wide array of application occasions and scenarios. Utilizing advanced Rotational Moulding Technology, this product excels in producing high-quality, durable items through the Rotational Casting Process. Its versatility makes it ideal for industries ranging from automotive and agriculture to consumer goods and industrial equipment.

In manufacturing, the Rotational Moulding Method employed by Youge allows for the creation of complex shapes with uniform wall thickness, which is crucial for producing large hollow parts such as tanks, containers, and playground equipment. The customizable color and size options, combined with surface treatments like polishing, sand blasting, and mirror finishes, enable businesses to tailor products according to specific aesthetic and functional requirements.

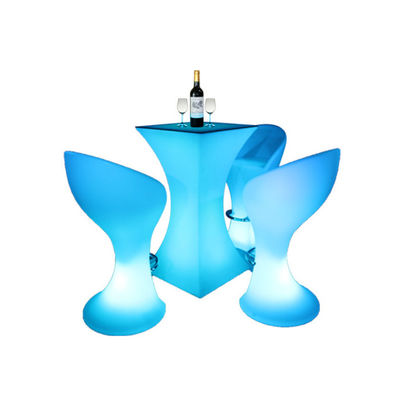

Outdoor and recreational applications benefit significantly from Youge’s Rotation Moulding product because of its smooth or textured surface finish options, providing durability and resistance to environmental factors. Products made using this Rotational Casting Process are ideal for outdoor furniture, kayaks, and storage solutions, where longevity and weather resistance are paramount.

Environmental considerations are also a key attribute of the Youge Rotation Moulding product. Utilizing recyclable materials and processes that generate low waste, this product aligns with sustainable manufacturing practices, making it suitable for eco-conscious companies seeking to reduce their environmental footprint.

The packaging details, including plastic bags, cardboard boxes, and wooden crates, ensure that each set arrives securely and in excellent condition. With a minimum order quantity of just 1 set and a negotiated price, the product offers flexibility and affordability for both small and large-scale production needs. Delivery time is typically 40-50 days, allowing for efficient planning and project execution.

Constructed from high-quality aluminum and steel mould materials, the product guarantees long service life and consistent performance in the Rotational Moulding Method. Whether for prototyping or full-scale production, Youge’s Rotation Moulding product is a dependable choice for a variety of industrial and commercial applications.

Customization:

Youge offers comprehensive Product Customization Services for Rotation Moulding products, specializing in Rotational Moulding Manufacturing. Our Custom Model is designed and manufactured in China, catering to a wide range of requirements with a minimum order quantity of just 1 set. We provide negotiated pricing to ensure competitive and flexible options for our clients.

Our expertise lies in the Rotational Molding Process, utilizing advanced thermoplastic molding techniques to produce parts ranging from small to very large sizes, reaching up to several meters. Whether you need smooth or textured surface finishes, we guarantee high-quality results tailored to your specifications.

As a reputable manufacturer, Youge ensures that all products feature UV and high-temperature resistance, enhancing durability and performance. Packaging is handled with care, using plastic bags, cardboard boxes, and wooden crates to protect your goods during transit. Delivery time is typically between 40 to 50 days, ensuring timely fulfillment of your orders.

Through our Rotational Molded Fabrication services, we deliver customized solutions that meet diverse industrial needs, combining precision, reliability, and innovation in every product we create.

Support and Services:

Our Rotation Moulding products come with comprehensive technical support and services designed to ensure optimal performance and longevity. We offer expert guidance on material selection, design optimization, and processing parameters to help you achieve the best results. Our team is available to assist with troubleshooting, maintenance advice, and training to maximize the efficiency of your rotation moulding operations. Additionally, we provide detailed documentation and access to the latest industry best practices to support your manufacturing needs.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped with protective materials and placed in sturdy, custom-designed boxes to prevent damage. We use high-quality cushioning to absorb shocks and vibrations, ensuring the product arrives in perfect condition.

For shipping, we partner with reliable logistics providers to offer timely and safe delivery worldwide. Tracking information is provided for all shipments, allowing customers to monitor their orders every step of the way. Whether shipping domestically or internationally, we prioritize the safe and efficient delivery of our rotation moulding products.

FAQ:

Q1: What is the brand name of the rotation moulding product?

A1: The brand name of the rotation moulding product is Youge.

Q2: Can I order a custom model for the rotation moulding machine?

A2: Yes, the rotation moulding product is available as a custom model to meet your specific requirements.

Q3: What is the minimum order quantity for this rotation moulding product?

A3: The minimum order quantity is 1 set.

Q4: How long does it take to deliver the rotation moulding product after placing an order?

A4: The delivery time is typically between 40 to 50 days.

Q5: How is the rotation moulding product packaged for shipment?

A5: The product is carefully packaged using a plastic bag, cardboard box, and wooden packaging to ensure safe delivery.

Q6: Where is the rotation moulding product manufactured?

A6: The rotation moulding product is made in China.

Q7: What is the pricing policy for the rotation moulding product?

A7: The price is negotiable depending on the order specifications and quantity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!