Product Description:

The rotational moulding product offers a versatile and efficient solution for manufacturing a wide range of parts, from small components to very large structures measuring several meters in size. This manufacturing technique, known as the Rotational Moulding Method, is highly regarded for its ability to produce complex shapes with uniform wall thickness, making it ideal for industries requiring durable and reliable plastic parts.

One of the key features of this product is its compatibility with various mould materials, including high-quality aluminum and steel. These materials ensure excellent heat distribution and durability during the rotational moulding process, contributing to consistent and precise results. The choice between aluminum and steel moulds allows for flexibility depending on production volume, cost considerations, and specific application requirements.

The product utilizes the thermoplastic molding process, which is a fundamental aspect of rotational moulding. In this process, powdered thermoplastic material is placed inside a hollow mould that is then heated and rotated biaxially. The rotation causes the plastic to melt and evenly coat the interior surfaces of the mould, forming a seamless and hollow part upon cooling. This method is especially effective for producing hollow items such as tanks, containers, and enclosures, which benefit from the strength and lightness of thermoplastic materials.

Environmental considerations are increasingly important in today’s manufacturing landscape, and this rotational moulding product addresses these concerns through the use of recyclable materials and processes that generate low waste. The ability to recycle the thermoplastic materials used in the Rotational Molded Fabrication not only reduces environmental impact but also enhances cost-efficiency by allowing material reuse. Additionally, the low waste characteristic of this process stems from the precise control over material distribution, which minimizes excess and scrap during production.

Another notable attribute of this rotational moulding product is the customizable surface finish options. Depending on the application and aesthetic requirements, the surface of the rotationally molded parts can be either smooth or textured. Smooth finishes are ideal for applications where a sleek appearance and easy cleaning are necessary, while textured surfaces provide enhanced grip, reduced glare, and improved resistance to scratches or wear. This flexibility in surface finish broadens the scope of potential uses and industries that can benefit from rotationally molded fabrication.

The Rotational Molded Fabrication process is distinguished by its cost-effectiveness and design freedom. Because the moulds are relatively simple and the process does not require high pressures, tooling costs are lower compared to other molding methods. This makes it particularly suitable for low to medium production volumes, custom designs, and prototypes. Moreover, the ability to create large, hollow parts without the need for assembly reduces labor and material costs, while enhancing the structural integrity of the final product.

In summary, this rotational moulding product embodies the advantages of the Rotational Moulding Method by combining size versatility, durable mould materials, environmentally conscious manufacturing, and adaptable surface finishes. Its reliance on thermoplastic molding ensures strong, lightweight, and seamless parts that meet diverse industry requirements. Whether producing small intricate components or very large parts spanning several meters, this rotational moulding product is a reliable choice for innovative and sustainable plastic fabrication solutions.

Features:

-

Product Name: Rotation Moulding

-

Color and Size: Customized to meet specific requirements

-

Material: High-quality Aluminum

-

Environmental Impact: Made from recyclable materials with low waste generation

-

Features: UV and high temperature resistance for durability

-

Product Size Range: Small to very large parts, up to several meters in size

-

Utilizes the Rotational Molding Process for efficient manufacturing

-

Incorporates advanced Rotational Moulding Technology

-

Supports flexible Rotational Moulding Production for diverse applications

Technical Parameters:

|

Environmental Impact

|

Recyclable Materials, Low Waste

|

|

Material Used

|

Polyethylene (PE), Polypropylene (PP), PVC, Nylon

|

|

Product Wall Thickness

|

4mm-8mm Customized

|

|

Surface Treatment

|

Polishing, Sand Blasting, Mirror

|

|

Mechanical Properties

|

Durable, Impact Resistant

|

|

Business Type

|

Manufacturer

|

|

Features

|

UV/High Temperature Resistance

|

|

Material

|

Aluminum

|

|

Shaping Mode

|

CNC Machining

|

|

Product Size Range

|

Small To Very Large Parts (up To Several Meters)

|

Applications:

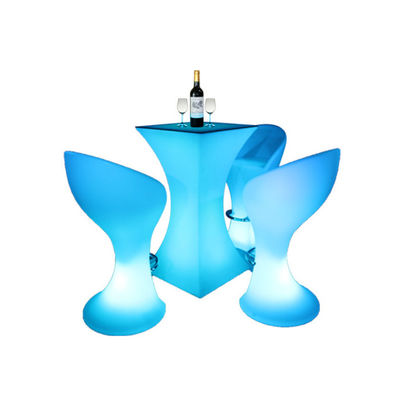

The Youge Rotation Moulding product, model Custom Model, originating from China, is designed to cater to a wide range of application occasions and scenarios. Utilizing advanced Rotational Polymer Moulding and Rotational Moulding Technology, this equipment is ideal for manufacturing durable and impact-resistant plastic products with either smooth or textured surface finishes. Its versatility makes it suitable for industries such as automotive, outdoor furniture, storage tanks, playground equipment, and custom industrial components.

In industrial manufacturing, the Youge Rotation Moulding machine excels in producing complex hollow shapes with consistent quality, thanks to its CNC machining shaping mode. This precision allows for custom designs that meet specific client needs, making it perfect for bespoke production runs as well as large-scale manufacturing. The product’s robust mechanical properties ensure long-lasting performance, even under demanding conditions, which is essential for applications requiring high durability and impact resistance.

Environmental considerations are also paramount with the Youge Rotation Moulding system. It employs recyclable materials and low waste processes, aligning with sustainable manufacturing practices. This makes it an excellent choice for companies aiming to reduce their environmental footprint while maintaining high product standards. The one-stop service offered by Youge further simplifies the procurement and implementation process, providing support from order placement to delivery.

With a minimum order quantity of just 1 set and a negotiated price structure, clients have the flexibility to engage with Youge Rotation Moulding solutions regardless of project scale. The packaging details, including plastic bags, cardboard boxes, and wooden crates, ensure safe and secure transportation. Delivery times typically range from 40 to 50 days, balancing manufacturing precision with timely fulfillment.

Overall, the Youge Rotation Moulding product is perfectly suited for a variety of application scenarios where rotational polymer moulding is essential. Whether producing large storage containers, intricate automotive parts, or durable outdoor products, this technology provides a reliable, efficient, and environmentally friendly solution that meets modern industry demands.

Customization:

Youge, a leading manufacturer from China, offers customized rotational moulding production services tailored to your specific needs. Our custom model supports a minimum order quantity of just 1 set, with pricing available upon negotiation to ensure the best value for your investment.

Specializing in thermoplastic molding processes, we utilize high-quality materials such as Polyethylene (PE), Polypropylene (PP), PVC, and Nylon to deliver durable and versatile products. Our rotational molded fabrication allows for a wide range of color and size customization, ensuring your product perfectly fits your requirements.

We provide a comprehensive one-stop service from design to delivery, with packaging that includes plastic bags, cardboard boxes, and wooden crates to guarantee safe transportation. Our typical delivery time ranges from 40 to 50 days, reflecting our commitment to quality and timely fulfillment.

Choose Youge for expert rotational moulding manufacturing that combines advanced technology with personalized service to meet all your product customization needs.

Support and Services:

Our Rotation Moulding product is designed to provide durable and high-quality solutions for a wide range of industrial applications. We offer comprehensive technical support to ensure optimal performance and longevity of your equipment.

Technical support includes assistance with installation, operation, maintenance, and troubleshooting. Our team of experts is available to guide you through best practices and recommend tailored solutions based on your specific needs.

In addition to technical support, we provide a variety of services such as routine maintenance programs, calibration, and repair services to minimize downtime and extend the life of your rotation moulding machinery.

We also offer training sessions for your staff to ensure they are well-equipped to operate and maintain the equipment safely and efficiently. Our commitment is to provide continuous support and service excellence throughout the lifecycle of your product.

For detailed product information, service requests, or technical inquiries, please reach out to our support team who are ready to assist you with expert advice and prompt solutions.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is wrapped in durable, impact-resistant materials and securely placed in custom-designed cartons to prevent movement and damage.

We use sturdy outer packaging with cushioning inserts to safeguard against shocks and vibrations. All packages are clearly labeled with handling instructions and product information for easy identification.

For shipping, we partner with reliable carriers to provide timely and safe delivery worldwide. Tracking details are provided upon dispatch, allowing you to monitor your shipment until it reaches your doorstep.

Whether shipping domestically or internationally, we prioritize the integrity of our rotation moulding products to ensure they arrive in perfect condition, ready for immediate use.

FAQ:

Q1: What brand is the Rotation Moulding product?

A1: The Rotation Moulding product is from the brand Youge.

Q2: Can I order a customized model for the Rotation Moulding machine?

A2: Yes, the product is available as a Custom Model to meet your specific requirements.

Q3: What is the minimum order quantity for this Rotation Moulding product?

A3: The minimum order quantity is 1 set.

Q4: How long will it take to deliver the Rotation Moulding machine after placing an order?

A4: The delivery time is typically between 40 to 50 days.

Q5: How is the Rotation Moulding product packaged for shipping?

A5: The product is carefully packaged using a plastic bag, cardboard box, and wooden materials to ensure safe delivery.

Q6: Where is the Rotation Moulding machine manufactured?

A6: The machine is manufactured in China.

Q7: What is the pricing structure for the Rotation Moulding product?

A7: The price is negotiable based on your order specifics and customization needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!