Product Description:

Rotation moulding, also known as rotational moulding, is a highly versatile thermoplastic molding process that enables the creation of hollow, seamless, and durable products. Utilizing the rotational moulding method, this manufacturing technique involves heating a thermoplastic material inside a mold that is continuously rotated along two perpendicular axes. This ensures even distribution of the molten plastic, resulting in uniform wall thickness and high-quality finished parts. The rotational moulding technology offers unparalleled flexibility in design, size, and material choice, making it an ideal solution for producing a wide range of products.

One of the most significant advantages of the rotational moulding method is its capability to produce parts that range from small components to very large structures, sometimes measuring several meters in size. This broad product size range makes rotational moulding technology suitable for diverse industries, including automotive, agriculture, storage tanks, outdoor furniture, playground equipment, and more. The ability to manufacture such a variety of sizes without compromising on product integrity or quality is a testament to the robustness of this process.

Customization is another key strength of rotational moulding technology. Manufacturers can tailor both the color and size of the products to meet specific customer requirements. Whether it is a vibrant color to enhance brand identity or a particular dimension to fit unique applications, the rotational moulding method supports extensive customization options. This flexibility ensures that clients receive products that are not only functional but also aesthetically aligned with their needs.

In terms of materials, the rotational moulding process primarily uses thermoplastics such as polyethylene (PE), polypropylene (PP), PVC, and nylon. These materials are chosen for their excellent durability, chemical resistance, and impact strength, which are essential properties for products exposed to harsh environments or heavy usage. Polyethylene (PE) is especially popular due to its versatility and cost-effectiveness, while polypropylene (PP) offers enhanced mechanical properties. PVC and nylon provide additional options for specialized applications that require specific performance characteristics.

Another advantage of the rotational moulding technology is its environmentally friendly nature. The process generates minimal waste because the exact amount of material required is used for each part. Additionally, the ability to recycle scrap and defective parts back into the manufacturing cycle further reduces environmental impact. This aligns with the growing demand for sustainable production methods in various industries.

To enhance the customer experience, many rotational moulding manufacturers offer a one-stop service that encompasses every stage of the production process. From initial product design and prototyping to material selection, molding, finishing, and delivery, this comprehensive service ensures seamless coordination and quality control throughout. Clients benefit from streamlined communication, reduced lead times, and consistent product quality, all facilitated by the rotational moulding technology.

In summary, the rotational moulding method stands out as a highly adaptable and efficient thermoplastic molding process, capable of producing a vast range of products in different sizes and colors. With materials such as polyethylene (PE), polypropylene (PP), PVC, and nylon, manufacturers can meet diverse application requirements while maintaining high durability and performance. The integration of a one-stop service further enhances the appeal of rotational moulding technology, making it an excellent choice for businesses seeking innovative, customized, and reliable plastic products. Whether for small parts or very large components, the rotational moulding method continues to be a leading solution in the field of thermoplastic molding.

Features:

-

Product Name: Rotation Moulding

-

Material: Aluminum

-

Surface Finish: Smooth or Textured options available

-

Features: UV and High Temperature Resistance

-

Process Type: Thermoplastic Molding

-

Shaping Mode: CNC Machining

-

Utilizes advanced Rotational Polymer Moulding techniques

-

Expertise in Rotational Molded Fabrication for durable products

-

Incorporates cutting-edge Rotational Moulding Technology for precision and quality

Technical Parameters:

|

Shaping Mode

|

CNC Machining

|

|

Features

|

UV/High Temperature Resistance

|

|

Service

|

One-stop Service

|

|

Product Wall Thickness

|

4mm-8mm Customized

|

|

Surface Treatment

|

Polishing, Sand Blasting, Mirror

|

|

Environmental Impact

|

Recyclable Materials, Low Waste

|

|

Surface Finish

|

Smooth Or Textured

|

|

Color And Size

|

Customized

|

|

Product Size Range

|

Small To Very Large Parts (up To Several Meters)

|

|

Mechanical Properties

|

Durable, Impact Resistant

|

Applications:

The Youge Rotation Moulding product, model Custom Model, originating from China, is a versatile and highly durable solution designed for a wide range of application occasions and scenarios. As a leading manufacturer specializing in Rotational Moulding Manufacturing, Youge offers customizable options with a minimum order quantity of just 1 set, making it suitable for both small-scale and large-scale projects. The product’s price is negotiable, allowing clients to tailor their purchase according to specific needs and budgets.

Utilizing high-quality materials such as Polyethylene (PE), Polypropylene (PP), PVC, and Nylon, this rotational plastic molding product boasts exceptional mechanical properties, including durability and impact resistance. With a customizable product wall thickness ranging from 4mm to 8mm, it provides enhanced strength and stability, making it ideal for applications that require long-lasting performance under various environmental conditions.

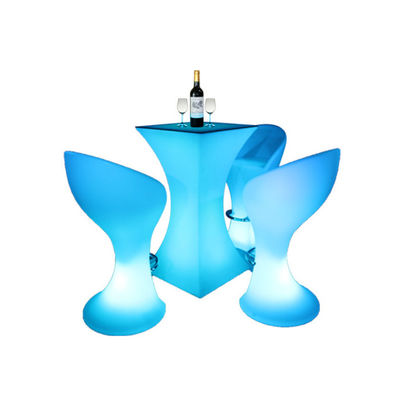

The Youge rotation moulding equipment excels in scenarios demanding UV and high-temperature resistance, ensuring that the finished rotational molded fabrication products can withstand harsh outdoor environments without degradation. This makes it especially suitable for producing durable outdoor furniture, water tanks, chemical containers, playground equipment, automotive parts, and industrial storage solutions.

In industrial settings, the rotational plastic molding process facilitated by Youge’s machinery allows manufacturers to produce complex, hollow parts with uniform wall thickness and minimal material waste. This technology is widely applied in sectors such as agriculture, construction, marine, and transportation, where robust and lightweight components are critical.

Packaging is thoughtfully designed to protect the equipment during transit, using plastic bags, cardboard boxes, and wooden crates, ensuring safe delivery within 40-50 days. Whether you are a startup or an established business looking to expand into rotational molded fabrication, Youge’s Rotation Moulding product offers a reliable, efficient, and customizable solution to meet diverse manufacturing needs.

Customization:

Youge offers premium Product Customization Services for Rotation Moulding products, tailored to meet your specific needs. Our Custom Model is designed and manufactured in China with a minimum order quantity of just 1 set, ensuring flexibility for all clients.

Utilizing the advanced Rotational Plastic Molding and Rotational Molded Fabrication processes, we employ the Rotational Molding Technique to create high-quality products with exceptional durability. Our process uses thermoplastic molding with materials such as Polyethylene (PE), Polypropylene (PP), PVC, and Nylon, all sourced to provide recyclable materials with low waste, emphasizing our commitment to environmental sustainability.

The mould materials used include both aluminum and steel, allowing us to achieve precise and reliable results. The surface finish of the products can be customized to be either smooth or textured, depending on your design preferences and functional requirements.

Each product is carefully packaged using a combination of plastic bags, cardboard boxes, and wooden materials to ensure safe delivery. Delivery time is typically between 40-50 days, and pricing is negotiable to best fit your project budget.

Choose Youge for expert rotational molding services that combine quality, customization, and eco-friendly practices in every product we deliver.

Support and Services:

Our Rotation Moulding products come with comprehensive technical support to ensure optimal performance and longevity. We provide detailed guidance on machine setup, process parameters, maintenance schedules, and troubleshooting tips to help you achieve the best molding results.

Our team of experts is available to assist with installation, calibration, and training to ensure your staff can operate the equipment efficiently and safely. We also offer customized service plans tailored to your specific production needs.

Regular maintenance services are available to keep your rotation moulding machines running smoothly, minimizing downtime and extending equipment life. Replacement parts and upgrades can be supplied promptly to support continuous operation.

Additionally, we provide consultation on material selection, design optimization, and process improvements to enhance product quality and reduce manufacturing costs.

For any technical inquiries or service requests, our support team is ready to provide timely and professional assistance to keep your rotation moulding operations running at peak efficiency.

Packing and Shipping:

Our rotation moulding products are carefully packaged to ensure maximum protection during transit. Each item is securely wrapped with protective materials to prevent any damage or scratches. We use sturdy, high-quality cartons and pallets designed to withstand handling and shipping conditions.

For shipping, we offer flexible options including sea freight, air freight, and land transportation to meet your delivery requirements. All shipments are tracked and managed to ensure timely and safe delivery. Additionally, we provide customized packaging solutions upon request to accommodate specific needs or branding preferences.

Before dispatch, every product undergoes a thorough quality check to guarantee it meets our high standards. Our logistics team coordinates closely with carriers to ensure smooth customs clearance and on-time arrival at your destination.

FAQ:

Q1: What is the brand and model number of the rotation moulding product?

A1: The rotation moulding product is from the brand Youge and comes with a custom model number tailored to your specific requirements.

Q2: Where is the rotation moulding product manufactured?

A2: The product is manufactured in China, ensuring high-quality production standards.

Q3: What is the minimum order quantity for this rotation moulding product?

A3: The minimum order quantity is 1 set, making it convenient for both small and large-scale orders.

Q4: How is the rotation moulding product packaged for delivery?

A4: The product is carefully packaged using a plastic bag, cardboard box, and wooden crate to ensure safe transportation.

Q5: What is the typical delivery time for the rotation moulding product after placing an order?

A5: The delivery time is approximately 40-50 days, depending on order specifications and production schedules.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!